If this product has an expiration or retest date, it will be shown on the Certificate of Analysis (COA, CofA). If there is no retest or expiration date listed on the product's COA, we do not have suitable stability data to determine a shelf life. For these products, the only date on the COA will be the release date; a retest, expiration, or use-by-date will not be displayed.

For all products, we recommend handling per defined conditions as printed in our product literature and website product descriptions. We recommend that products should be routinely inspected by customers to ensure they perform as expected.

For products without retest or expiration dates, our standard warranty of 1 year from the date of shipment is applicable.

For more information, please refer to the Product Dating Information document: https://www.sigmaaldrich.com/deepweb/assets/sigmaaldrich/marketing/global/documents/418/501/product-dating-information-06-25-mk.pdf

About This Item

Skip To

Product Name

D.E.R.™ 332, used as embedding medium

InChI key

LCFVJGUPQDGYKZ-UHFFFAOYSA-N

InChI

1S/C21H24O4/c1-21(2,15-3-7-17(8-4-15)22-11-19-13-24-19)16-5-9-18(10-6-16)23-12-20-14-25-20/h3-10,19-20H,11-14H2,1-2H3

SMILES string

CC(C)(c1ccc(OCC2CO2)cc1)c3ccc(OCC4CO4)cc3

Quality Level

Looking for similar products? Visit Product Comparison Guide

1 of 4

This Item | D3415 | 15138 | 731811 |

|---|---|---|---|

| Quality Level 200 | Quality Level 100 | Quality Level 100 | Quality Level 100 |

Application

Disclaimer

Legal Information

related product

signalword

Warning

hcodes

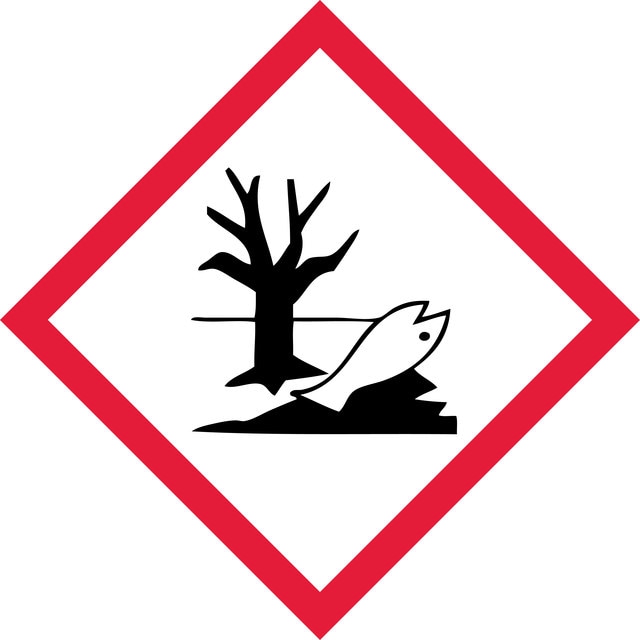

Hazard Classifications

Aquatic Chronic 2 - Eye Irrit. 2 - Skin Irrit. 2 - Skin Sens. 1

Storage Class

10 - Combustible liquids

wgk

WGK 1

flash_point_f

507.2 - 514.4 °F - closed cup

flash_point_c

264 - 268 °C - closed cup

ppe

dust mask type N95 (US), Eyeshields, Faceshields, Gloves

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

-

How can I determine the shelf life / expiration / retest date of this product?

1 answer-

Helpful?

-

-

How is shipping temperature determined? And how is it related to the product storage temperature?

1 answer-

Products may be shipped at a different temperature than the recommended long-term storage temperature. If the product quality is sensitive to short-term exposure to conditions other than the recommended long-term storage, it will be shipped on wet or dry-ice. If the product quality is NOT affected by short-term exposure to conditions other than the recommended long-term storage, it will be shipped at ambient temperature. As shipping routes are configured for minimum transit times, shipping at ambient temperature helps control shipping costs for our customers. For more information, please refer to the Storage and Transport Conditions document: https://www.sigmaaldrich.com/deepweb/assets/sigmaaldrich/marketing/global/documents/316/622/storage-transport-conditions-mk.pdf

Helpful?

-

-

If you order an epoxy resin, does it include a hardener?

1 answer-

The product D.E.R.™ 332 refers to the epoxy resin component only. It does not include a hardener. Epoxy resins generally require a separate hardener or curing agent to initiate the curing process and achieve the desired properties.

Helpful?

-

Active Filters

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service