Sélectionner une taille de conditionnement

1 210,00 $

1 210,00 $

A propos de cet article

Passer à

Fabricant/nom de marque

Novagen®

Conditions de stockage

OK to freeze

1 of 4

Cet article | 70922 | 70584-M | 70751 |

|---|---|---|---|

| manufacturer/tradename Novagen® | manufacturer/tradename Novagen® | manufacturer/tradename Novagen® | manufacturer/tradename Novagen® |

| storage condition OK to freeze | storage condition OK to freeze, avoid repeated freeze/thaw cycles | storage condition OK to freeze, avoid repeated freeze/thaw cycles | storage condition OK to freeze |

Description générale

Autres remarques

•10,000 UBenzonase Nuclease, purity >90%

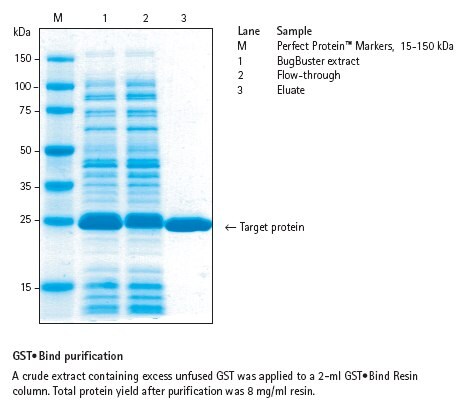

•10 mlGST•Bind Resin

•pkg/4Chromatography Columns

•2 x 100 ml10X GST Bind/Wash Buffer

•40 ml10X Glutathione Reconstitution Buffer

•1 gGlutathione, Reduced

Informations légales

Clause de non-responsabilité

Mention d'avertissement

Warning

Mentions de danger

Conseils de prudence

Classification des risques

Flam. Liq. 3

Code de la classe de stockage

3 - Flammable liquids

Point d'éclair (°F)

96.8 °F

Point d'éclair (°C)

36 °C

Certificats d'analyse (COA)

Recherchez un Certificats d'analyse (COA) en saisissant le numéro de lot du produit. Les numéros de lot figurent sur l'étiquette du produit après les mots "Lot" ou "Batch".

Déjà en possession de ce produit ?

Retrouvez la documentation relative aux produits que vous avez récemment achetés dans la Bibliothèque de documents.

Contenu apparenté

E. coli transformation with poly-histidine tagged constructs represents a common vehicle for protein production. Initial screening of small-scale cultures is routinely performed to identify clones producing the highest amounts of protein with the desired form and function. As the demand for greater throughput at this level has increased, so has the need for process simplification and greater reproducibility. To meet this need, we have developed a condensed workflow that can be performed in a single device.

Traditionally, protein purification from E. coli consists of four distinct phases: harvest, bacterial cell lysis, lysate clarification and protein purification. Bacterial lysis typically requires several time-consuming, hands-on steps, such as freeze/thaw cycles and sonication. These harsh lysis techniques may negatively impact protein quality and contribute to sample-to-sample variability. To maintain protein activity and integrity, detergent-based lysis buffers are routinely used to avoid mechanical protein extraction methods. Regardless of the lysis method used, centrifugation is traditionally required to pellet unwanted cell debris and permit recovery of the clarified lysate. The final step, purification, is frequently performed using affinity media specific for expressed epitope tags. Agarose-based media have typically been used, either as a slurry in microcentrifuge tubes or packed into gravity-driven or spin columns. While easier to manipulate, columns are greatly affected by lysate consistency and carryover of cell debris, which can lead to clogging of the column frits.

Active Filters

Notre équipe de scientifiques dispose d'une expérience dans tous les secteurs de la recherche, notamment en sciences de la vie, science des matériaux, synthèse chimique, chromatographie, analyse et dans de nombreux autres domaines..

Contacter notre Service technique