Polymer Synthesis Techniques

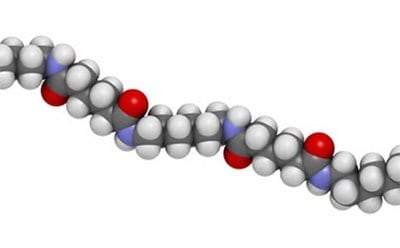

Polymers are a class of materials comprising small repeating chemical units. The building block or the repeating unit in the polymer is called a monomer. Polymerization, or polymer synthesis, is a chemical reaction in which monomers are joined together by covalent bonding to form polymer structures. The length of the polymer chain is characterized by the number of repeating units in the chain, which is referred to as degree of polymerization (DP). The molecular weight of the polymer is the product of the molecular weight of the repeating unit and the DP. The basic properties inherent to polymers mainly depend on the molecular weight, structure (linear or branched), and DP.

Featured Categories

We provide reliable polymerization tools to initiate and manipulate a chemical reaction of monomers to form polymer chains or networks with specific properties for diverse applications.

Discover our selection of polyethylene glycol (PEGs) and PEG derivatives in a wide range of molecular weights for all your PEGylation needs and applications.

We offer an extensive range of natural and synthetic biomedical polymers with advanced properties suitable for all your biomedical applications.

Explore our portfolio of versatile hydrophobic polymers to support your adhesion, coating, fiber, film, engineered plastic and biomedical applications.

Based on the types of chemical reaction involved, polymerizations are grouped into two types, known as condensation and addition polymerization. In condensation or step-growth polymerization, a condensation reaction takes place between two different bi-functional or tri-functional monomers to produce polymers, whereby small molecules, often water, are eliminated from the reaction. In addition polymerization, or chain-growth polymerization, the growth of the polymer occurs by adding monomers to active sites on the polymer chain with regeneration of the active sites at the end of each growth step. An initiator is required to produce the initiator species with reactive centers. The reactive center can be a free radical, cation, anion, or organometallic complex.

The characteristics of polymers are highly dependent on monomer types and the polymerization method used for the synthesis. Living radical polymerization, also referred to as controlled radical polymerization (CRP), enables better control over the polymer molecular weight, molecular weight distribution, functionality, and composition. CRP can be utilized with a wide range of vinyl monomers to build polymers with diverse properties for different applications.

There are three fundamental CRP techniques:

- Atom transfer radical polymerization (ATRP)

- Reversible addition/fragmentation chain transfer (RAFT) polymerization

- Nitroxide-mediated polymerization (NMP)

ATRP is well-suited for surface modification applications which rely on tailored hydrophilicity, adhesive properties, or nanoparticle functionalization. Polymers derived from both RAFT and ATRP can be modified post-polymerization and are used extensively in the biomedical field for drug delivery and tissue engineering applications. Block copolymers for biomedical applications, are commonly developed from RAFT or ATRP. Block copolymers, developed from NMP, are essential for pigment dispersion, memory devices, and composite manufacturing.

Visit our document search for data sheets, certificates and technical documentation.

Related Articles

- Find reversible addition–fragmentation chain transfer(RAFT) polymerization process, classes of RAFT agents & applications.

- Literature values for the glass transition temperature, (Tg), and melting temperature, (Tm), are given for the more common homopolymers.

- Refractive index (RI or n) is of critical importance for photonics applications such as optical waveguides and ophthalmic devices. Based on their unique refractive index characteristics and good optical clarity, polymeric materials are also used as anti-reflective coatings for solar cells, displays and contact lenses.

- MALDI-TOF MS is useful for monitoring complete conjugation. Functionalized polymers are useful for creating polymer conjugates for diverse applications.

- ATRP is a successful method for precise polymer synthesis with controlled molecular weights and high chain end functionalities.

- See All (46)

Related Protocols

- Polymerization via ATRP procedures demonstrated by Prof. Dave Haddleton's research group at the University of Warwick.

- Polymeric spheres serve as crystal templates. Synthesis methods yield large quantities.

- RAFT polymerization offers precise control, enabling tailored synthesis of complex polymer structures.

- We present an article about RAFT, or Reversible Addition/Fragmentation Chain Transfer, which is a form of living radical polymerization.

- We presents an article featuring procedures that describe polymerization of methyl methacrylate and vinyl acetate homopolymers and a block copolymer as performed by researchers at CSIRO.

- See All (6)

Find More Articles and Protocols

How Can We Help

In case of any questions, please submit a customer support request

or talk to our customer service team:

Email [email protected]

or call +1 (800) 244-1173

Additional Support

- Chromatogram Search

Use the Chromatogram Search to identify unknown compounds in your sample.

- Calculators & Apps

Web Toolbox - science research tools and resources for analytical chemistry, life science, chemical synthesis and materials science.

- Customer Support Request

Customer support including help with orders, products, accounts, and website technical issues.

- FAQ

Explore our Frequently Asked Questions for answers to commonly asked questions about our products and services.

To continue reading please sign in or create an account.

Don't Have An Account?

![4-Cyano-4-[(dodecylsulfanylthiocarbonyl)sulfanyl]pentanoic acid 97% (HPLC)](/deepweb/assets/sigmaaldrich/product/structures/204/925/30ae6ca0-5b0b-4963-a061-7e5e3d1a85af/640/30ae6ca0-5b0b-4963-a061-7e5e3d1a85af.png)